Laboratory facilities

- Infrared thermal camera

- Spline couplings test rig

- 3D hexapod displacement measuring device

- Fatigue test machines

- Oven for high temperature fatigue tests

- Modal analysis equipment

- Contact pressure measurement device

- Free wheels stiffness measurement device

- System for active and passive thermography with lamps (up to 3000W) and laser (50W) sources, amplitude and frequency modulation

-

Hot Disk system for thermal transmissivity and diffusivity measurements 2 and 6 mm diameter sensors

Welding system

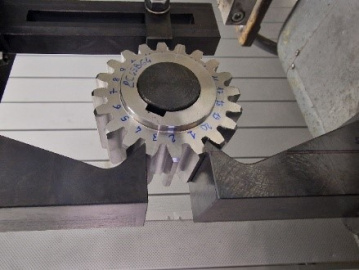

Gear fatigue testing equipment

The equipment allows to test gears of different sizes using a mechanical pulsator (or vibrophore). The teeth of the gear wheel are subject to bending fatigue by applying the load in the most severe "Single Tooth Contact Point" condition (ISO6336-Part3). Furthermore, the point of force application is identified using the Wildhaber rule to reduce positioning error.

-

Test bench for wear and durability tests on splined couplings operating with angular misalignment.

The test bench has a mechanical power recirculation type scheme which allows the power necessary for its operation to be reduced to a minimum. The bench allows you to test a splined coupling by imposing a misalignment angle between the two parts of the splined coupling (shaft and hub), this allows you to study the effect of the angular misalignment on the life of the component under test and evaluate its effects on wear of the component itself. The splines under test can be lubricated (with oil or grease) or run dry.